Getting your winch cable snapped in the middle of nowhere is not an uncommon thing. If you’re not ready for such situations in prior, you won’t have an escape from there.

So, knowing a few winch cable repair tips and hacks will definitely help you get out of a stuck situation. If you end up with a broken steel cable or a snapped synthetic rope, help is here.

We’re discussing how you can come by despite having a broken wire or snapped rope on a winch. You’ll also get some winch cable maintenance tips so that you don’t have to deal with a broken cable sooner than you anticipated.

Let’s get started.

Can You Repair a Cracking Winch Cable?

Repairing a winch cable should not be an issue if the cable is repairable enough. If you end up snapping the cable on either end of it, chances are you’re good to go with it.

However, if you break it in the middle point and the remaining length isn’t enough for your job, you probably want to go for a new cable. So, it’s all about the length, how much you’re cutting off.

Winch Cable Repair – Step-By-Step Troubleshooting Guide

Repairing a winch cable is not that hard if you can follow the right winch cable repair guide. So, let’s talk about the repair methods for each type of winch cables, along with how you can make a clean eyelet.

Fixing a Steel Winch Cable

The first type of winch cable we’re repairing is the steel wire that usually snaps under load heavier than rated. Treating it bad under adverse conditions can weaken it, leading to a snap quicker than it meant to be.

You’ll need a wire cutting plier, and a cable clamp or just some sort of tape.

To repair a steel cable, you need to prepare it for the process. First, cut the burred, damaged portion, keeping the good side intact. It can be 2-3 feet into the snapping point.

Making a Quick Eyelet:

Once you have a good cable end to work with, you can now make a new eyelet to get going. Here’s how you do it:

- Strip off 16-18 inches of the cable. If it’s a 7-wire cable, split them by 3 and 4.

- Make an eyelet at the connecting point, keeping the size as large you want.

- Now, re-do the unwinded cables making sure the cable is splicing into itself.

- Pull through the eyelet and keep the grooves in place lined up nice and snug.

- Once you reach the end point, wind the rest of the cable to itself (all 7 strands).

- With the whole cable winded again, it already is enough strong to get going.

- But you also want to keep it neat, so put on a cable clamp or use tape to secure that.

Don’t forget to use a pair of gloves while dealing with the burred steel wire though. This video gives you a nice presentation of the process described above:

Repairing a Synthetic Winch Cable

If you’re using a synthetic rope instead of a steel wire, it’s safer and easier to work with as it’s flexible.

You also should keep in mind while getting a synthetic rope winch for ATV is, it should come with long enough rope that covers your off-roading adventures. This is so that you have enough room to do repair jobs.

First, use a pair of scissors or a sharp blade to cut the damaged part of the rope. Now you can start working with the remaining intact part of the rope.

Making an eyelet on a synthetic rope requires only one tool, and that’s a rope fid for feeding the cable well.

Follow this guide to make an eyelet so that you can have a new rope ready to go into action:

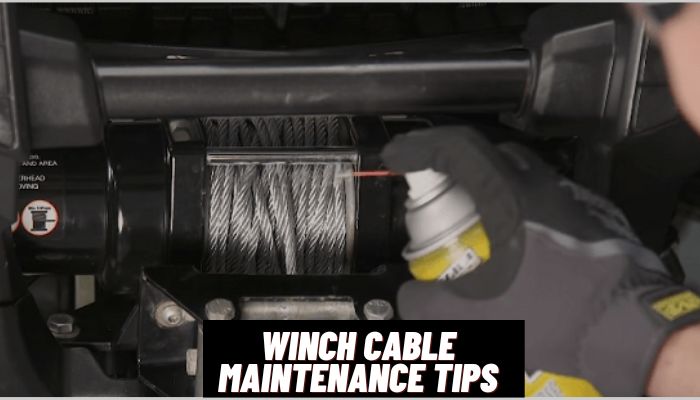

Maintenance Tips For Winch Cable

Maintaining your winch cable is what you want to learn to keep it in good shape for a really long time. For steel cables and synthetic, the maintenance tips can vary. We’ll talk about them both.

Keep Your Cable Dry

Steel or Synthetic, you must keep the winch cable nice and dry if you don’t want to end up damaging it sooner than it’s rated for.

Every time you use it, make sure it’s completely dry before resting for long. Steel cable will develop rust if left wet, and synthetic will start weakening as well.

Apply Lubricants

Before every use, be sure to put on lubricant to the wire so that you have the flex in place. You can find lubricants for both steel cables and synthetic ropes.

Also, use lubricant while storing the cable for a long time as it will keep it out of rust. The same thing applies for synthetic rope as it also can get damaged by UV rays.

Avoid Dirt While Storing

Storing the cable or rope while it has dirt or grime to it will damage the cable in no time. As you won’t use the winch on a daily basis, even while off-roading, keeping it clean and free from dirt is your best bet to keep it safe.

Examine Regularly

Inspect the cable or rope regularly for weak points where it can start to degrade on. Steel cables start to develop rust after having a yellowish coating. If you see any, take action and treat it with cleaning and spraying.

Do The Replacement in Time

Whenever you end up with a damaged or completely rusted winch cable, be sure to replace it in time. Never use a damaged or worn-out cable; it may put you in danger if snapped while you’re around the cable while pulling.

Spool with Tension

This is especially applicable for synthetic rope in order to keep it in good shape every time you spool in and out. If you don’t spool while keeping the tension on and roll in order, the rope will overlap on each other line, eventually having to cut it open.

Bottom Line

After ending up with a damaged winch line, if it’s on one side and still usable for your use case, don’t throw it away! The winch cable repair guides above should be enough to help you get out without seeking help just to tow you out.

Keep safety concerns in mind while working with winch lines, especially steel wires. Put on gloves to avoid accidents and take proper care of the cable to last longer.

Recent Posts

It’s relatively easier when you’re buying a brand-new winch as you can choose one with cable or rope pre-installed. But when you’re planning on replacing the current cable winch, you will...

When you’re planning to mount a winch to your trailer, it’s easy and common to get confused. There are too many options in deciding the style and hoisting method. A bad connection, an...